Advanced Manufacturing

Advanced Manufacturing

Service hotline

Service hotline

+86 -10 -84721682

+86 -10 -84721386

+86-315-5079899

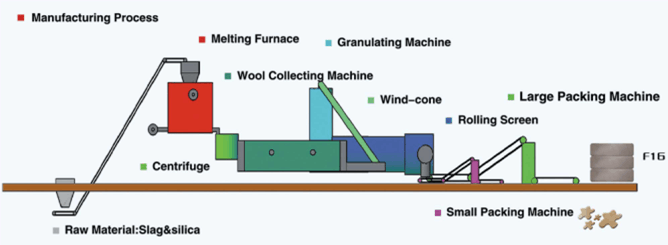

Mineral wool production process

NewTime Foundation mineral wool is used blast furnace slag, basalt, silica as raw material, according to the ratio of automatic weighing, the delivery, mixing, upgrading, the ingredients into the melting furnace, the raw material in the melting furnace to fully melt, After desulfurization emissions. The melt flows out from the lower material inlet of the melting furnace and is introduced into a high-speed centrifuge. The high-temperature melt flowing into the centrifuge is thrown into fibers under the combined effect of centrifugal force and high-speed airflow, and the fibers are blown to a wool collecting machine. Negative pressure wind machine sucked down to the level of operation set wool nets, was granulated into the granulation system to form a certain granular fibers, depending on the use of different particle size can be adjusted within a certain range, from the granulation Machine output of granular wool can be directly into different specifications according to different uses of packaging storage, can also be transferred to other manufacturing lines, the production of friction and sealed particulate fiber and mixed hard wool.