Products & Application Summary

Mineral wool for Friction& sealing industry

Service hotline

Service hotline

+86 -10 -84721682

+86 -10 -84721386

+86-315-5079899

Review of Frictional Seal Mineral Fibers

Our products

NewTime Foundation mineral fiber are made from nature basalt, diabase, silica and others as raw material, fiber chemical stability, high temperature resistant, corrosion resistant, do not contain asbestos ingredient absolutely safe for human health and environment.

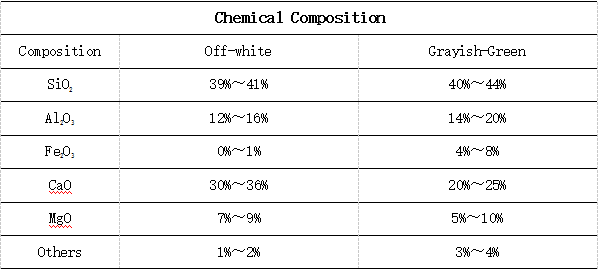

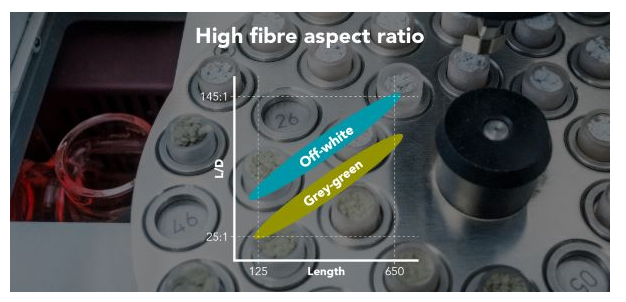

There are two main kinds of mineral fibers in the base industry, one is grayish-green and the other is off-white. Both products have unique attributes, and the range of applications is obviously different. Fiber has passed REACH,Non- asbestos by SGS technical service co., LTD,Also Non-asbestos detection and biodegradable detection testing by China's National non-metallic mineral products quality supervision center.

The NewTime mineral fiber product application field is very extensive, including friction, water treatment, track, coating, gasket and fence etc., With more than ten years of professional knowledge and experience,Company keeps pace with the times to adapt the changing market demands.

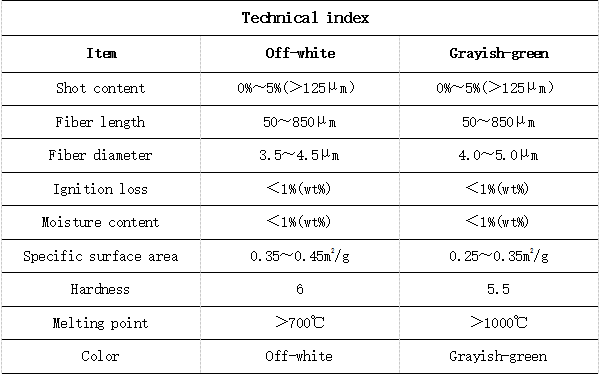

Product parameters

Product performance

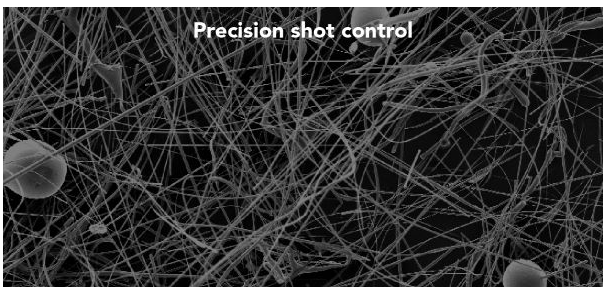

1.Lower shot

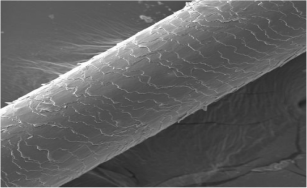

Fiber in the process of production by the melt spun process or blowing into fiber viscosity range in a flash to brittle viscosity range, in this moment most melt were led into fibrous mineral fiber, but there are still a part of the melt into granular without forming fiber, block and the club, we collectively known as shot.The NewTime Foundation is base precise control, the shot content can be reached to 0.1%.

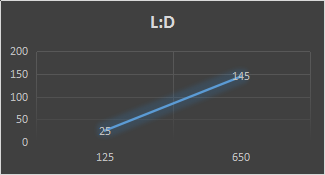

2.High length to diameter ratio

The NewTime Foundation base mineral fiber length-high ratio, and the size is stable

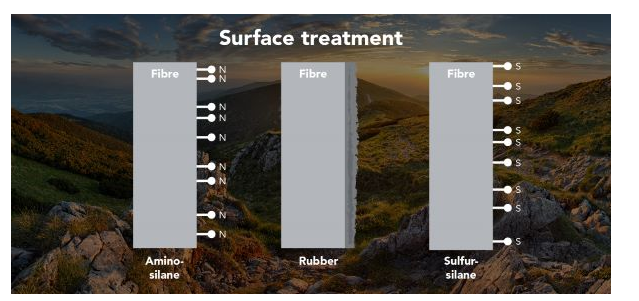

3.Surface treatment

We can treat the fiber with different surface treatment methods, such as amino-silane, sulfhydryl silane, cationic primer and so on.With different surface treatments, we can produce different fibers for different applications industry.

Product application

The NewTime Foundation mineral fiber that fiber is mainly used to strengthen the brake block and brake pads etc. Friction parts, gasket and sealing elements, paint and coating properties .

Friction Industry

The brake system is the most important safety component of all vehicles, so it is very important to maintain the friction film with stable friction performance under any extreme conditions.Friction plate is the outcome of combined action of all raw materials, the performance of the new inheritance mineral slag ball fiber rate, good dispersibility, high temperature resistance, corrosion resistance, can improve the friction performance of friction plate and mechanical properties.

1) Reduced brake noise 2)Reduce brake dust 3)Friction coefficient stability

Gasket Industry

NewTime Foundation sealing special mineral fiber is specifically for seal product research and development, high temperature resistance, corrosion resistance, the advantage of length- diameter ratio, fiber can enhance the gasket mechanical strength, compressive strength , creep properties, etc.

Coating

NewTime Foundation mineral fiber is pure mineral fiber, which is made of natural raw materials and it is a healthy and safe inorganic fiber.The fiber is used in the coating which can improve the coating mechanical property and the high temperature performance, to make the coating more durable.The fiber is purity inorganic fiber, the ignition loss is low, In the high temperature condition will not release poisonous gas, It is the ideal raw material for the production of fire retardant coating.